Operational Excellence for Facilities Management

What immediately comes to mind when you hear the phrase “facilities management”?

If you are similar to the average person, you immediately think of “Janitorial Services”, “Property Maintenance” and other comparable and rather mundane tasks associated with the more superficial aspects of maintaining a building and its surrounding property. You might even think of routine preventative and remedial maintenance of infrastructure items within the building itself. And you would not be entirely incorrect in answering thus – just grossly incomplete.

According to a report “The long-term cost of buildings” published by the Royal Academy of Engineering, one can conservatively expect that the building maintenance and operating costs to be five (5) times as much as the construction costs of the building over the lifetime of the asset. Also, the business operating costs (utilities and the like) can be conservatively estimated at two-hundred (200) times as much as the construction costs of the building.

According to Anthony Serdula, President of A. Anthony Corp (a firm that specializes in the management of commercial and industrial facilities), “We consistently see companies not tracking the spend details related to the maintenance and operation of their facilities. They pay little attention to insurance coverage and costs, maintenance agreements, unit pricing on labour – all of it. They don’t track this information because it’s just not their core business – none of it is directly related to delivering their product or services. So they end-up overspending, or spending on the wrong things.”

So, for example, if a building costs $10 million to build, then it will cost $50 million to maintain and an estimated $2 BILLION to operate over its lifetime. We are not just talking mopping the floor and cutting the grass at these numbers.

Where does all of the money go?

Some of the more obvious sources of cash out-flow are;

- Preventative maintenance (PM): These are the costs associated with proactively preserving a building and keeping it in its optimal state of readiness to task and efficiency. However, much like how we treat our health – and though it is the most cost-effective form of maintenance – we tend to forego this relatively nominal form of investment until something breaks-down.

- Remedial maintenance (RM): These are the costs incurred as a result of an unplanned and unmanaged breakdown in a facility. The costs incurred to remedy a situation are almost always significantly higher than performing Preventative Maintenance. In addition to paying expediting costs to effect the repairs rapidly, there are “disruption costs” associated with the negative impact of the repair on the productive activities of the business.

- Lost efficiencies: These are the costs incurred as a result of infrastructure items not working at their optimal level of efficiency. For instance, an HVAC unit that is not properly maintained (or incorrectly sized or installed) might cost as much as 70% more to operate in increased energy consumption to perform the task and a far greater number of breakdowns due to being overworked.

What about some of the lesser considered sources of cash out-flow?

- Demolish a building you don’t own: Yes, this happens. I know of a Fortune-500 Company who needed extra parking space. They decided to demolish an old building on the property to make room for it. Unfortunately, it was not their building to demolish, but a building they leased. OOPS!

- Hire an uninsured repair company: Oftentimes, the manager of a facility just needs a job to be done and, not knowing who to hire, asks their colleagues. The referral might be someone who did some personal repair work and is not a bonafide company. If you hire such a person to do work on commercial property, your exposure to risk might be enormous. For instance, if they (or one of their workers) get hurt while working at your facility, you can become liable for their injuries – which may or may not be covered under your Worker’s Compensation policy. Or, if they caused damage and disabled a production line, you might not have any recourse to augment the loss as such firms probably don’t have the means to pay a judgment.

- Hire a firm with undocumented workers: You risk running afoul of the law if the workers you hire do not have the proper work-documents to work. Although this is primarily the responsibility of the employer of the worker, you can find yourself in violation of the law if you simply and indirectly have an illegal cutting your grass.

- Hire incompetent workers: It happens all the time; firms tend to hire the cheapest resources they can find – and not the “best value” (a balance between quality and price). How many times have you hired someone because they were the least expensive only to have them take a magnitude more time to PROPERLY complete the job? Did you ever have to hire someone else to correct the mistakes of the first person we hired? Seek to hire the best value.

- Under-utilizing maintenance contracts: When a piece of equipment or building infrastructure item breaks down and needs to be repaired – do you always check to see if the equipment is under warranty or that there might exist a maintenance contract to cover (or help cover) the expense of repair? Perhaps the contract even covers Preventative Maintenance? How often do you hire-out the repair only to discover later that it was covered under an agreement? And more importantly, how often do you not make the discovery?

- Effecting repairs that are not your responsibility: If you lease your building or other property, how often do you check the lease documents to ensure you are responsible for the repairs that need to be affected? Do you fix that leaking roof, or HVAC unit, or plumbing without looking at the lease to ensure it’s your responsibility? Did you know that, in most cases, if you affected the repairs without allowing the landlord to affect the repairs himself, it’s your problem?

What can be done?

With so much at stake, it is prudent and justifiable to engineer and deploy an Operational Excellence for Facilities Management (OpEx for FM) program, leveraging the approach and toolsets of Lean Six Sigma in the management of your facilities. Laying the ground-work for the program will not be an easy undertaking, but much of it can be done with administrative-level personnel with the guidance of the facility “Sherpa”, who has been around long enough to have all the local knowledge and experience needed – the first real work activity will be to inventory the infrastructure of the entire facility.

What is it? Assign an inventory number, create a description of the item, identify where it is located and obtain its purchase documentation. Who owns the asset? It is very important to note who owns the item – not least for which you don’t destroy it accidentally on purpose – but also for noting who is responsible for what maintenance.

What warranties and maintenance agreements do you have in effect and what are their coverages? Who’s responsible for its maintenance (both preventative and remedial)? Organize copies of the warranties and maintenance agreements making notations as to when the agreements expire, their costs, and what is included/excluded.

According to Serdula; “It’s very common to see Operational Excellence or Lean Six Sigma programs being deployed at our clients in their production processes – they just don’t think about expanding these programs to the maintenance of their facilities. Or even worse, they try to introduce personnel who are not trained in Facilities Management – and who don’t understand the related business processes – and expect them to improve the running of their facilities. The only thing worse than putting in no resource is putting in a resource that doesn’t know what’s going on, what the goals should be, and how to go about achieving them. Inevitably, they do more harm than good.”

However, all that is just the execution of part of the first step of an overall OpEx for FM program. Many things have to be done in advance before the program is launched.

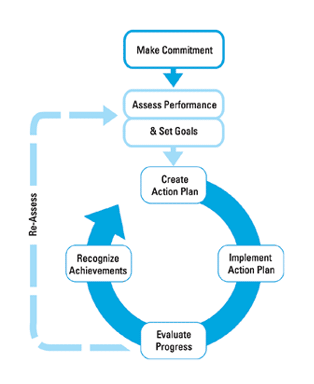

![1]() Pre-launch phase

Pre-launch phase

STEP 1: Make commitment: Before you embark on an OpEx for FM program, you have to be convinced of the benefits and committed to seeing it through (this means dedicating budget and resources LONG TERM). If you don’t commit, STOP NOW… the program will fail.

STEP 2: Assess performance: Create a “Present State Value Stream Map (VSM)” of how things work now. Make sure to note the costs and delays (both direct and indirect) associated with the non-value-add steps and quantify losses incurred due to the inefficiencies and failures (as well as risk analysis) of the system as it presently exists.

STEP 3: Set goals: Create a “Future State Value Stream Map” of how the vision of the future will look and what the expected value (and savings) are expected to be.

STEP 4: (PLAN) Create action plan: Once the Future State is defined, create a program to evolve the processes from their Present State towards their Future State. This program will then be sub-divided into a series of individual plans and Kaizen Events (complete with defined goals) to incrementally move you from where you are to where you want to be. If you expect that this will occur quickly, you would be profoundly wrong. The program will take considerable time and resources – which is why it needs commitment. But the savings projected by comparing the Present State and Future State should justify the program (if it does not justify the program, STOP).

STEP 5: (DO) Implement action plan: Begin the process in earnest – continuously, deliberately and sustainably. Do not try to unduly compress the timelines as you will only achieve burn-out, the program will stall, and then it will fail. Set a pace for the program roll-out that is sustainable and not frantic. Slow and steady wins the race.

STEP 6: (CHECK) Evaluate progress: Every plan or Kaizen Event should have the expected objectives of the exercise clearly stated. Upon completion of the project or Kaizen Event, conduct an unbiased and impersonal “debrief” – evaluate your expectations versus your achievements. How did you do? What could have been done better? What worked, what didn’t and why? Be honest, or the failures will be amplified as you go forward.

STEP 7: (ADJUST) Reassess: Take the feedback and lessons learned from the debriefs and consider them in the execution of the program going forward.

STEP 8: Recognize achievements: It is very important to maintain morale and let the team members know they are on an important mission for the company. So, win, lose or draw – recognize the accomplishments and efforts of those involved in the program. It is especially important to recognize failure in a positive manner. Nothing stifles innovation and enthusiasm faster than punishing those who take risks.

What are the expected results?

A company should reasonably and conservatively expect a saving of 20% in the cost of maintaining and running their building over its lifetime by deploying a cohesive and comprehensive OpEx for FM program. Using our example at the beginning – namely a facility that cost $10million to build – the savings you can be reasonably expected to realize is more than $400 million.

Serdula is even more aggressive, “We typically can achieve a 35% decrease in recurring spends when a facility is managed properly. It’s not easy and it’s not quick – in fact, it takes a lot of work and commitment. But the results that can be realized – and the return on investment – can be HUGE”. Now that’s a number worth building on…

Joseph, you raised some excellent points in your article. I was a facilities director for a building and semiconductor R&D lab, its more complex then running a mfg line.