The Operational Excellence manifesto

Definition: “Operational Excellence is when the efforts throughout the organization are in a state of alignment for achieving its strategies and where the corporate culture is committed to the continuous and deliberate improvement of company performance AND the circumstances of those who work there – to pursue ‘Operational Excellence by Design’ and not by coincidence.” – Joseph F Paris Jr; Chairman, XONITEK Group of Companies.

Over the past few years, I have increasingly seen a great many organizations (companies and academia) and professionals (practitioners and consultants) attempt to hijack “Operational Excellence” in an attempt to “rebrand” the disciplines of “Lean Six-Sigma” or “Continuous Improvement”. Admittedly, some programs do try to build a differentiator by sprinkling some “soft skills” such as “Leadership” or “Culture Change” on their program.

But this is a wholly inadequate determination and merely a subset of what Operational Excellence is all about today and how it was initially conceived some several years ago.

Take, for instance, an advertisement I just received for the Operational Excellence Lean Sigma conference to take place in Berlin this coming November (which is just one of the hundreds of examples I can offer; it just happens to be the most recent). Whilst the conference appears to offer considerable value for those interested in the tools and techniques related to Lean Six Sigma, it falls very short of anything resembling “Operational Excellence”. If you take a look at the abstracts for each of the talks, each has an emphasis on some aspect of Lean Six Sigma, but none of them speaks to a company’s efforts which are outside of production, supply chain and delivery. Where are the talks which involve finance, marketing, sales and other aspects of a company – and their respective roles in pursuing Operational Excellence? Why not just call the conference “Lean Sigma” [sic]? Would anyone notice the difference?

History of Operational Excellence

If we look into the past (using a “Google Search” for “Operational Excellence YYYY”), there is a dearth of significant detail with regards to “Operational Excellence” before 2002 – and what is it is very thin. In 2002, the Association Society for Quality (ASQ) advertised an article entitled “How to Achieve Operational Excellence” and the “keywords” included “Business Plans, Commitment, Communication, Continuous Quality Improvement (CQI), Performance Objectives, Cost Management, Goals, Quality Management (QM)” – no mention of Lean Six Sigma and none of the associated buzz-words.

In 2003, the United States Coast Guard (USCG) initiated an Operational Excellence Program where the criteria were to “…provide Coast Guard Auxiliary boat crews with a challenging opportunity to highlight their proficiency and skills, foster teamwork, and encourage fellowship among operational members.” To the USCG, Operational Excellence was all about performing as a team with an exceptional level of proficiency in completing the tasks necessary to result in mission successes. In my opinion, this program embraces the spirit of Operational Excellence.

In November of 2003, the Economist Intelligence Unit (a division of “The Economist” magazine), published a report commissioned by Celerant Consulting called “Strategy Execution: Achieving Operational Excellence”. It surveyed 276 executives in North America with fifty-per cent (50%) of the respondents being from the “C-Suite” from across various industries. The interesting thing about this analysis is that it’s a survey whose intent is to measure the importance and impact of “Operational Excellence”, but nowhere does it state what “Operational Excellence” might be. It’s obvious by reading the questions that there is a spin for leveraging technology as some means of achieving Operational Excellence. However, the only thing one seems to gain for reviewing is that top-performing companies have “… more committed management, make better and more frequent use of performance data and management mechanisms, and have stronger communication channels to link senior management with frontline employees.” I read that and can’t help but think, “Duh – no kidding.” But again, no direct connections or correlations between Operational Excellence and Lean Six Sigma are made.

By far, one of the more interesting position papers I came across was a paper from DuPont from 2005 entitled, “Delivering Operational Excellence to the Global Market – A DuPont Integrated Systems Approach”. It’s a fairly detailed document, but after reading it a few times, I came away feeling that it was disconnected and/or incomplete. Although the document spoke to Operational Excellence and its achievement, it never defines it anywhere. How can one know if one has achieved Operational Excellence (or even on the right path) if one does not know what it looks like?

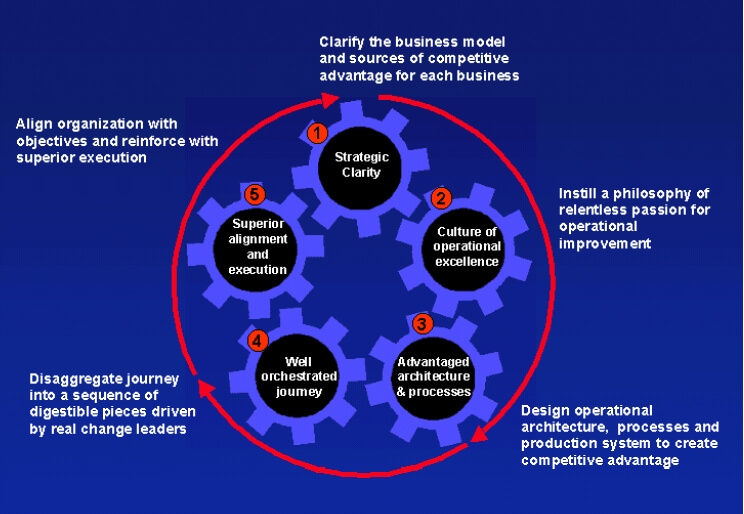

There seemed to be a conflict in messaging where the philosophies were presented graphically and never addressed, but what was addressed were the details of the approach and no reference to the philosophies. This left me feeling that the graphics were created and presented by the “strategists” at DuPont, but the verbiage describing the program was created by the “tacticians” who implemented, as demonstrated by the following graphic and associated text: a) “Taking the journey toward Operational Excellence typically begins with making an initial step-change improvement, followed by a continuum of incremental enhancement. Installing a culture of Operational Excellence results in a significant and sustained competitive advantage.” And b) “A study by the Board of Manufacturing and Engineering (formerly the Manufacturing Studies Board) of the US National Research Council showed that the companies that effectively implemented world-class manufacturing systems achieved improvements in asset productivity performance.”

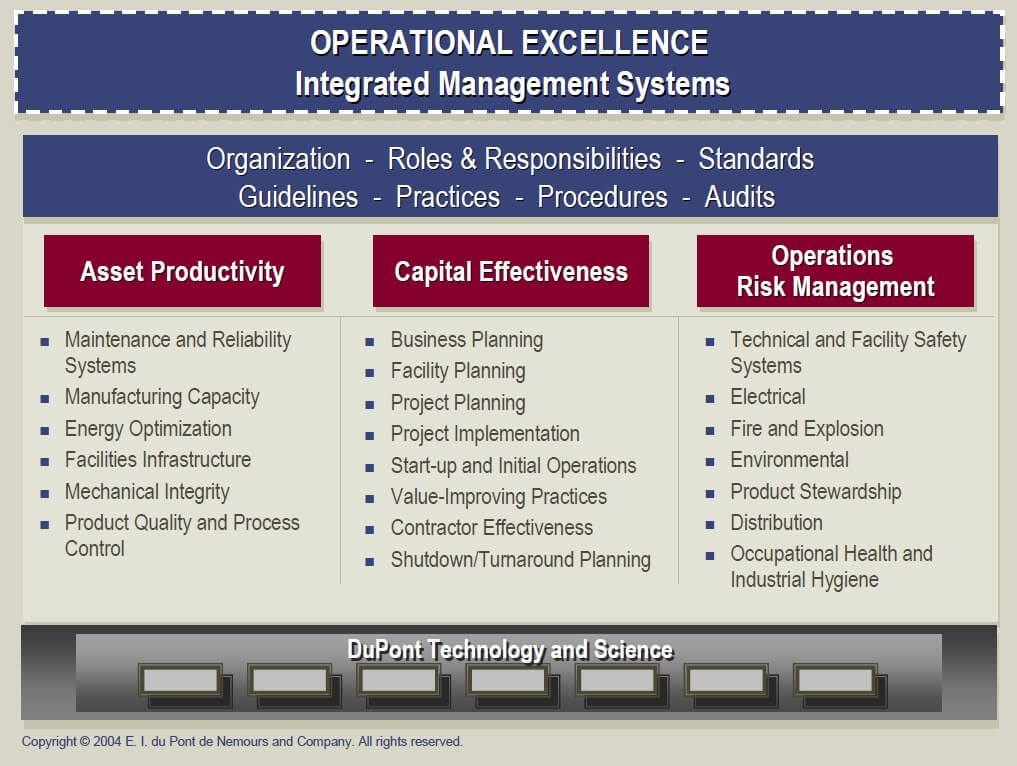

While I thought the graphic went a long way in illustrating the concepts of Operational Excellence, the content spoke more to Continuous Improvement and, in fact, specifically mentioned “world-class manufacturing systems”. This seems to be a conflicting message; certainly, it makes it unclear and confusing. However, DuPont did demonstrate that it felt Operational Excellence had three aspects:

Asset Productivity, Capital Effectiveness and Operational Risk Management as shown in the following graphic. But again, there is no mention made of Lean Six Sigma being a component of the program.

The model for Operational Excellence used by Storebrand (a Norwegian finance and insurance company) in its “Capital Market’s Day” presentation in October of 2006 (see next graphic) is very nearly identical to the Operational Excellence Integrated Management System from DuPont. It is interesting to note that the major difference between the two models is that Storebrand lists the customer first and DuPont does not list the customer at all. There is very little mention of Lean Six Sigma (except for “Lean Project”) and it is very apparent that Storebrand differentiates Operational Excellence from Lean Six Sigma.

I appreciated the approaches used earlier by ASQ, and I especially enjoyed the definition used by the US Coast Guard in their Operational Excellence Program. But it still would appear that the definitions used are inconsistent across the companies that embrace Operational Excellence – with most of these individual definitions also being incomplete.

Defining Operational Excellence as Lean Six Sigma is like defining a Vehicle as an Automobile – the latter of each being a subset of the former, but not the same. And I swear; if I read one more definition of Operational Excellence being about “Flow”, I am going to wretch. What good is flow if you have no orders for the product? Or you have no way of collecting the information to build/provide? Or you have no business? A definition of Operational Excellence has to embrace the entirety of the organization.

Organizational considerations for Operational Excellence

So, if Operational Excellence isn’t just about “Customers”, “Capital / Assets”, or “Processes / Operations”, or “People” or even “Flow”; then what is Operational Excellence all about and what part of the organization is involved (or even should be involved)? For your consideration, an extensive (if incomplete) list of business requirements and functions that must be embraced and integrated into any true Operational Excellence program:

- Entity – What is the best type (sole proprietorship, limited liability company, partnership, corporation) and structure for the entity (investor terms and conditions)? Where is the best place (the state where the company holds office or some other) for the entity to be formed?

- Professional Services – Finance and Accounting; who are the “legal eagles”, accountants and financial advisors for the company and their respective expertise? Is their expertise in alignment with the requirements of the company?

- Finance – What is the best capital finance structure for the organization? Are the investors strategic and what is their exit strategy? How much equity versus debt? What is the collateralization of the debt and what are the covenants associated with the loans?

- Development (Design Engineering) – Who is the principal designer of the service or product offerings? What do they need to come-to-market and then perpetuate the value?

- Facilities and Production Assets – Where are the production facilities to be located and what characteristics are required for the facility site (existing talent pool, roads, internet, airport, utilities, taxes, etc…)? What is needed to produce the product or service?

- People Resources – I dislike “human resources” and prefer “people resources” – but in any case, what talent is required to produce, deliver and service the offerings? How do you find them and how do you effectively onboard them?

- Marketing – Let’s assume you have a great offering that people will want – how do people know? Who is your customer, how do you reach them and what’s your messaging? Are you sure that is the message they want to hear?

- Sales – Hurray! They like your messaging! Now, how do you get them to turn that attraction into a transaction – to monetize your offering? You do realize that without this transaction occurring, there is no need to worry about “pull” or “flow”, right?

- Front-Office Operations – We need to make sure the business entity is running smoothly and that the transactions (and all related details) are moving through the entity with as much accuracy and velocity, but with as little friction as possible. Is that happening?

- Supply Chain – Do your suppliers know what you need (product and/or services), to what specifications, in the quantities that you need it, and when you need it by? How do they know all of this? How do YOU know all this?

- Production (whether a product or service) – How do you generate the product or services most efficiently and effectively?

- Logistics & Delivery – How do you efficiently and effectively convey the ownership of your product or services from you to the customer?

- Post-Sale Service – Once you convey your product or service to the customer, how do you keep them happy with their having placed their trust in you?

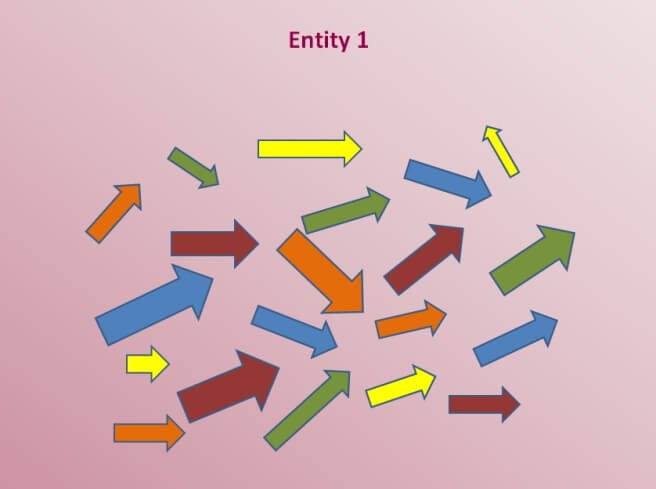

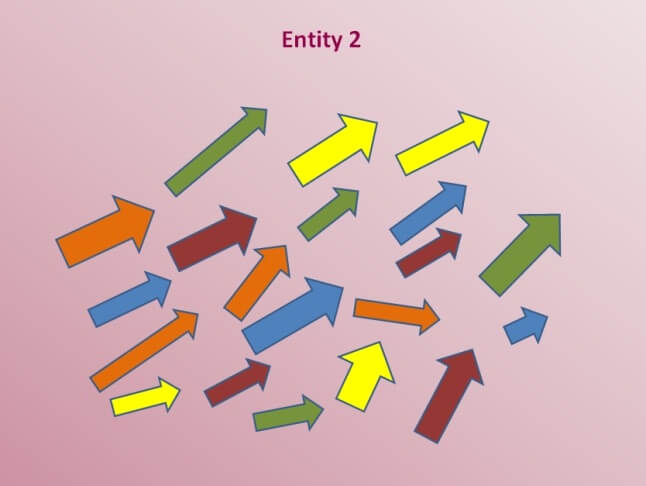

Since all of these various dimensions must be considered if an organization were to have a hope in achieving any reasonable level of Operational Excellence, how can such a discussion only involve the disciplines associated with Lean Six Sigma? Or even if you toss-in Leadership and/or Culture Change? Which of the organizations below do you believe is more likely to achieve Operational Excellence?

Or

The one which is more aligned and committed? Or the one which is less? Which are you?

Definition of Operational Excellence

So, what exactly is Operational Excellence? Where is there an adequate definition which transcends the Strategic, through the Tactical and Logistical, and to Execution – and does so in a manner that embraces the entirety of the organization and its collective efforts? Through my studies, analysis and work over the past several years – work which cuts across all industries, geographies, and cultures – and by my own experiences and observations in owning the Operational Excellence Group on Linked-In and in my founding the Operational Excellence Society; I propose the following “Definition of Operational Excellence”:

“Operational Excellence is when the efforts throughout the organization are in a state of alignment for achieving its strategies and where the corporate culture is committed to the continuous and deliberate improvement of company performance AND the circumstances of those who work there – to pursue ‘Operational Excellence by Design’ and not by coincidence.” – Joseph F Paris Jr; Chairman, XONITEK Group of Companies

So let’s break this definition down. “Operational Excellence is…”

– “… when the efforts throughout an organization…” – all efforts in any capacity, every calorie or cash expended, through-out the entirety of the organization and its value-chain.

– “… are in a state of alignment…” – there exist communication and transparency such that unity of purpose, and being, are realized.

– “… for achieving its strategies…” – the goals of the organization have been effectively conveyed and that all assets, resources and efforts are focused on attaining those goals.

– “… and where the corporate culture is committed to…” – there exists an ethos throughout the organization that it is unreservedly devoted to the effort. This is a function of effective Leadership, Stewardship, Mentorship, and Followership all existing.

– “… the continuous and deliberate…” – not just always moving forward, but moving forward in an intentional and calculated manner; with not only a sense of purpose but purpose itself.

– “… improvement of company performance…” – This simply means to improve Profit; aka, the “Bottom-Line”, “EBIDTA”, “Shareholder-Value”, and whatever other euphemism that can be conjured up in the name of “Political Correctness”. There are many ways to facilitate the realization of increased profits – but make no mistake, businesses exist to make profits and their improvement efforts must yield greater profits.

The efforts to improve company performance should ensure the company is always innovative and competitively positioned in its value-proposition to its present and future customers and to drive both short-term and long-term value. These efforts include (but by no means should be considered an exhaustive list): aligning the development of the offerings of the company to the desires of market-place and ensuring the messaging and sales efforts are effective in positioning these offerings; making sure that the finance and equity structure are optimal to support the strategies of the company; validating the efficiency and effectiveness of the supply chain; and all other considerations including those which involve operations such as “Lean Six Sigma (LSS)”, “Theory of Constraints (ToC)”, “Total Quality Management (TQM)”, “Enterprise Resource Planning (ERP)”, and the entire alphabet-soup of other management methodologies are embraced in the definition – and yes, even “Flow”.

– “… AND the circumstances of those who work there…” – in addition to improvements in company performance, improvements in the circumstances of those who make the company successful must also be equally considered. I specifically do not specify “pay” or “compensation”, because it’s been my experience that what is important to each individual varies by the person (or group of people). Most people will not leave a company for 5% (or 10% or even more) in pay. They will leave if they feel disenchanted, disrespected, detached or under-valued. They want a sense of pride and ownership. They want their lives to be more joyous and they want to look at their job as a means to that joy. Company leaders who “get this” will reap great rewards both professionally and personally.

It is a colossal mistake for companies to believe that they can improve company performance just by heaping more and more on the backs of the employees – it’s unsustainable and there is a breaking point which will eventually be reached. The company needs to set its pace for a marathon, not a sprint – there needs to be enough energy in reserve for a “kick” when needed.

– “…to pursue…” – this is a never-ending quest and will not ever be achieved.

– “… Operational Excellence by Design…” – that this quest must be conducted with a sense of purpose and in an engineered fashion with: clearly defined goals; clear and concise plans communicated effectively and transparently; proper commitment, support and alignment throughout the organization; and strong leadership (and followership) during execution.

– “… and not by coincidence.” – Operational Excellence cannot be achieved by accident.

It has taken me a very long time to develop this definition (with many revisions over time and with even one made during the writing of this article) and I am sure there will be many of you who disagree with me – however, discourse and debate are fair and welcome. After all, even the definition of Operational Excellence should be subject to the mantra that is Operational Excellence; without the opportunity to improve upon it would be hypocritical.

This definition, applied throughout an organization and its value-chain – from its vendor’s vendor to its customer’s customer – is the “Manifesto of Operational Excellence”… and, if pursued with vigilance, will result in your becoming a “High-Performance Organization”

Great confirmation of what so many others expressed at Google on this topic. Nevertheless it is easier said than done. Vast majority of Opex/LSS/CI initiatives wrongly deployed and unsustainable confirms that.

What does this definition do differently that help companies achieve Operational Excellence in sustainable manner? I am interested

What my definition does for a company is nothing much by itself; merely just words on a page. What will help a company is if a leader finds that my definition can be adapted to serve as their lighthouse and chart a course for themselves.

… That being said, I have written a couple of additional articles on the subject which more specifically address your question;

https://opexsociety.org/body-of-knowledge/eulogy-of-a-continuous-improvement-program/

https://opexsociety.org/body-of-knowledge/continuous-improvement-must-be-more-than-cost-savings/

Hello Joseph Paris

What does this definition do differently that help companies achieve Operational Excellence in sustainable manner?

Best Regards

A definition serves as a lighthouse. And certainly, my definition of Operational Excellence serves as my lighthouse on the subject. But, while most people describe operational excellence, few actually define it. And even fewer define it without using the term in the definition.

… As for what my definition does for a company is nothing much by itself; merely just words on a page. What will help a company is if a leader finds that my definition can be adapted to serve as their lighthouse and chart a course for themselves.

I have worked in both manufacturing and service industries. Two thoughts came to mind as I read this. One being that the list of functions, business requirements and tasks needed for Operational Excellence resemble Project Management Planning. The second thought was that, weaved in and amongst the functions and tasks, there needs to be thorough documentation of processes followed by a rigorous adherence to them. Process documentation and discipline in following processes helps an operation perform consistently and predictably.

What better definition of Operational Excellence that watching at what Japanese companies so far have done in sustainable fashion?

Any thoughts?

Q: What better definition of Operational Excellence that watching at what Japanese companies so far have done in sustainable fashion? Any thoughts?

A: For your consideration, I believe the supposed prowess of Japanese companies might be largely, if not entirely, a myth. Certainly, it is an exaggeration. I wrote an article on this very subject and do a deeper dive in one of the chapters of my book, “State of Readiness”

https://josephparis.me/my-articles/lean-reality/