6 Common Reasons for Six Sigma Initiative failure

Six Sigma Initiative Failure

This article identifies 6 common reasons for failure in Six Sigma initiatives. I don’t like focusing on failure, however, an understanding of common reasons for failure will, at a minimum, enable practitioners to go into an investment in Six Sigma with their eyes fully open. It will also ensure they can maximise the possibility of success.

- The first reason relates to a lack of benefit quantification. There are actually two potential issues here – are there any benefits, and if so, are they being identified accurately and reported upon? Obviously, the first is a much bigger problem, and if there are no business benefits the entire program will need to be reconsidered.

- Lack of management buy-in. This reason is closely linked to the first. If there are few benefits and/or they have not been clearly identified, only a disinterested senior management team would continue to “support” the program anyway. Effective senior management teams are often not noted for their patience, and any investment not delivering clear ROI in today’s world is likely to have a short life.

- Lack of tangible results from a pilot. As with reasons 1, the third reason links closely to the 2nd. I would argue that a common reason for a pilot in the first place is that the executive team are not totally convinced of the business benefits, so a pilot is arrived at as a compromise. Pilots are easy to kill with a minimum amount of fuss as opposed to a high profile executive commitment across a business.

- Lack of coaching and skills. Again, this reason in linked to the others. A lack of coaching and skills, will in many cases, be associated with a relatively weak Six Sigma team – the kind of team that may struggle to get the executives fully bought in.

- Lack of resources. Getting sufficient numbers of “belts” trained at whatever levels is a major investment, not only in actual cash for the training, but in terms of time and adding extra work to busy managers’ lives.

- Is it seen as too complicated? In some quarters, Six Sigma is regarded as too complicated. There’s a lot of terminology surrounding the concept and that doesn’t always help either. Admittedly, nothing really worthwhile is achieved easily, but there is the sense that Six Sigma is sometimes more effort than impact.

So, one thing that does emerge clearly is that the reasons for failure tend to be linked and have a lot to do with the quality and experience of the Six Sigma team and their ability to sell the business benefits to the executive.

We have seen that one of the best ways to ensure that the business benefits are visible to the executive team is to establish an explicit link between operational excellence activities and strategy implementation or deployment.

In order to do this, many successful companies have adapted their approach to operational excellence tools to ensure the actions and tasks in their projects are linked to transformational goals. In many cases they have found Hoshin type planning processes can be used as an effective tool to ensure the essential links between breakthrough strategic objectives to annual objectives, to the tasks in the programs and projects including Six Sigma continuous improvement initiatives.

As all improvement activities need to be aligned through to one or more of only four to five top level breakthrough objectives, this results in prioritisation and a reduction in the number of operational excellence projects, reducing the complexity and number of resources required. The use of the collaborative catchball process considerably increases the quality of the objectives and metrics that are developed as well as the engagement and buy-in of employees, across the business to achieve them, including the leadership team.

Other Hoshin process activities, including monthly and annual review meetings, during the execution period will also assist. These meetings provide a forum to view planned and actual performance against metrics aligned to the breakthrough objectives.

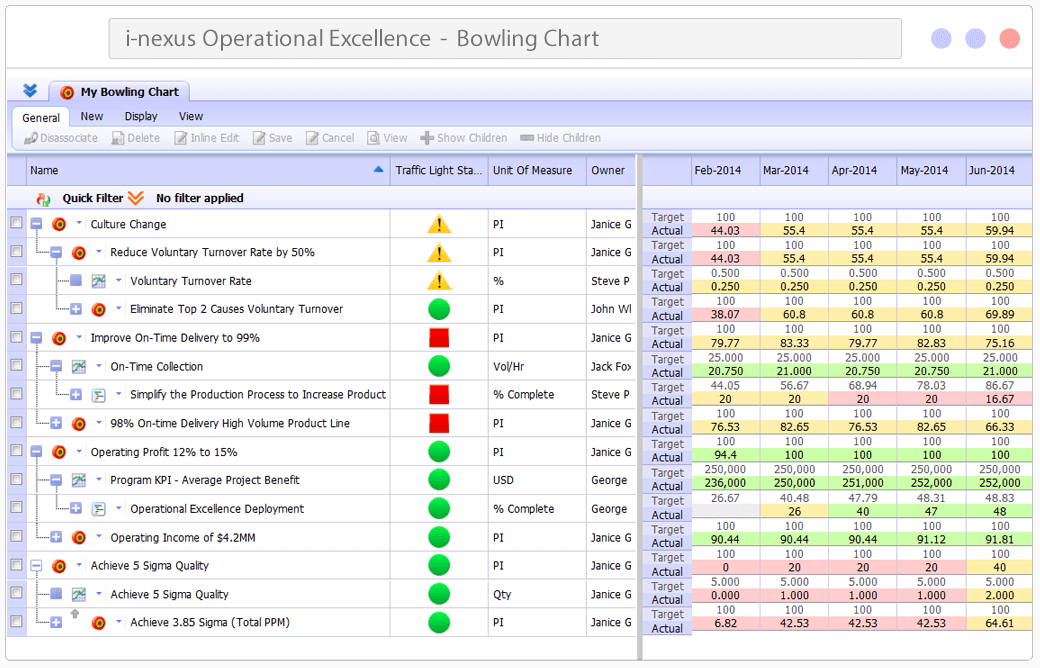

Tools such as a bowling chart highlight where actual performance falls short and provide high visibility of the situation as well as the opportunity to decide on countermeasures to ensure the targets are met, significantly increasing the likelihood of improvement project success.

When enabled by enterprise software, continuous improvement teams could also ensure that the executive team could not only look at benefit realisation in individual improvement projects, but also at the aggregate programs and the overall program KPIs at an enterprise level. This will ensure that employees, including executives, based on their user access rights, will be able to track any associated benefits through standard easy to access and read reports, demystifying the real value the programs are adding to achieve their breakthrough objectives across the business.

Accordingly, in linking continuous improvement projects to strategic objectives of the business, this will provide continuous improvement teams with an effective tool to prove the ongoing business benefits of process excellence activities to their leadership teams. Doing this in terms of what they see as important to them i.e. achievement of overall strategic objectives, it will ensure ongoing executive sponsorship, and reduce the likelihood of failure of these projects well into the future.

It is for the first time I see realistic reasons for Six Sigma failures. Excellent analysis.

Thanks for the insight. I know there are a lot of companies who have tried to implement Six Sigma and failed, but they are not sure why the initiative failed. This sheds some light on potential roadblocks to Six Sigma implementation. Thanks.

We have implemented 6 sigma succesfully, but beofre launching this program is to stabilize your operations, you can not improve nothing without having a standard and a base line.

To stabilize the operation you must have all your equipment at the best possible conditions, provide maintenance to your equipment, train your workforce on standard work, implement routines checks to minimize the variation.

Make sure you have a good gauge system in place and once you have the minimun of stability you can start to improve and reduce the variation among the system.

Therefore the first step is to move from chaos to standards, then optimization and control.

6 sigma fails because it requires a strong control systems once the projects have identified the proper process and process conditions, these bennefits will get lost if the improved system is not in control.

then all your findings must be back to your FMEA to assure your organization that these new critical characteristics are tracked and monitored to avoid out of control spikes.

It is not just tracking projects it is setting a system in your organization that maintains and sustains the bennefits.

it is a cultural implementation.

A tracking board is OK but it is just a part of the 6 sigma initiative.

We have implemented 6 sigma succesfully, but beofre launching this program is to stabilize your operations, you can not improve nothing without having a standard and a base line.

To stabilize the operation you must have all your equipment at the best possible conditions, provide maintenance to your equipment, train your workforce on standard work, implement routines checks to minimize the variation.

Make sure you have a good gauge system in place and once you have the minimun of stability you can start to improve and reduce the variation among the system.

Therefore the first step is to move from chaos to standards, then optimization and control.

6 sigma fails because it requires a strong control systems once the projects have identified the proper process and process conditions, these bennefits will get lost if the improved system is not in control.

then all your findings must be back to your FMEA to assure your organization that these new critical characteristics are tracked and monitored to avoid out of control spikes.

It is not just tracking projects it is setting a system in your organization that maintains and sustains the bennefits.

it is a cultural implementation.

A tracking board is OK but it is just a part of the 6 sigma initiative.

Look at the reasons why the top management doesn’t trust these initiatives. The 4 last reasons are strong contributors, but the two first ones are clear symptoms of failed 6S set up.

Companies that have problem with their set up would do good to use outside help to assess the real problems. Outside help has typically dedicated time (they sell their time), clear focus (no vested interest or internal politics) and required skills and method to deal with these problems.

Software is good to help and support the management operating system and actual management. However, the operational base need to be solid and function without software for it to be a sound investment.

Excellent analysis, thanks for the insight and sharing this with us.

I appear to be an outlier in most discussions. However, having been associated with Six Sigma since the development, on the original team to train the world’s first black belts and master blackbelts plus a primary facilitator in the early days at GE, I have a strong conviction that weak cultures are the major cause of failed execution of strategic planning, project management and lean six sigma projects. Articles on studies found in Harvard Business Review, Wall Street Journal, Forbes and others claim failure rates are over 50%.

We built the trading courses for SiX Digma at Motorola but GE made Six Sigma a world movement because of the strong GE Culture created by Jack Welch. Weak culture is characterized by poor communication, fear of telling the truth, lack of trust and poor conflict resolution. Most business schools do not teach MBAs how to build a strong culture. It is a human capital development challenge. World Class business schools are making the necessary adjustments. However, the majority fail to recognize and execute a term DR. Mikel Harry coined in his creation of Six Sigma, BREAKTHROUGHS! Without breakthrough goals any system, organization and individual will stagnate and ultimately fail.

Just my humble opinion. Lol

Thanks for the clear analysis Paul,

I would like to drop a comment further exploring reasons behind.

Your article does address the functional reasons, and the previous reply also addressed culture as underlying root cause? Coming from the Dutch Area, I often see a kind of allergy and even stonewalling as soon as Six Sigma or Lean programs are perceived as exploiting people rather than supporting them.

It is my opinion that as soon as we succeed in authentically connecting the management (with their goals) to the daily work practice, even a weaker culture can develop a successful program. I sometimes feel like coaching the frontline leaders through the program, eventually leading to better shopfloor management, based upon pride of workmanship. Only then system goals can be adopted by the the improvement teams in a non-conflicting way.

IMHO, you really don’t have to go past number one, but this is not a 6 Sigma issue alone. Very few organizations have a solid (or any) methodology of objectively QUANTIFYING risk and return and thus no real way to prioritize projects/initiatives. Now as an example, if your company uses and ordinal scale of say 1-5 to CLASSIFY risk your process is borderline worthless.

It worthless because it leaves far to much guess work. That usually boils down to cultural fights for resources and then everything else on this list soon follows. When one solves this they’ll be surprised how everything tends to solve itself. As Charles Kettering was quoted, “A problem well defined is mostly solved”.

I don’t agree with any of those highlighted common reasons. What buy in? Six sigma must be driven from the top. It’s how it was designed and how it should work. Culture and discipline are the main ingredients of its success.

Root causes found following rigorous analysis based from credible and valid data must be acknowledged, no ifs no buts must be fixed and must not be compromised.

Realized savings must be hard and must be in the P&L.

If these are followed then, no way six sigma could fail.

Paul Docherty Finally someone who understands the need for data, and peer review. Love the graph, and would love to see the actual data (and how the experiment was designed). Others I’ve queried can only give ‘everyone knows this’, and anecdotal accounts (as well as the old ‘well, uh, it’s proprietary’). I’m sure you’ve done your homework, let’s get into it. Please share.

Thanks for the article: “reasons for failure tend to be linked and have a lot to do with the quality and experience of the six sigma team and their ability to sell the business benefits to the executive”

That’s just has to do with Lack of Organization Readiness and Lack of Governance & Stakeholder Management. That’s why vast majority of Six Sigma/Lean/LSS/CI initiatives are wrongly deployed. These confirm that:

Bain Management and Tools 2007 Survey

Six Sigma ‘killed’ innovation in 3M | ZDNet

Top 10 Reasons Lean Six Sigma Projects Fail

Question is: From your personal experience: Why after so many years still people keep missing somethng critical and keep doing something wrong when deploying SS/LSS/CI initiatives?

Paul, thanks for the article. It would have been good to know what kind of companies you gathered this data from. Were they only firms that also use I-Nexus with their 6 Sigma programs? I am seeing a relatively newer threat to success for six sigma. I call it counterfeit training. Some firms offer certified Green Belt training in 2 days and certified Black Belt training in 4 days. I will bet money that such Six Sigma programs are also unsuccessful. Thanks again for the article.

Exactly! Good question; why should management buy-in be such a desperate request from Six Sigma experts. It should be initiated by management in the first place, rather than management playing this role of wanting to be woed into a CQI relationship.

It is also important for lean/Sigma SMEs to be assertive in insisting that the right methodologies are used. Powerful stakeholders with little CQI knowledge interfere in deployments, sometimes thwarting the scientific rigour of the process.

Thanks for all the exchanges.