Lean transformation and visual management

How a small designer’s team made the Lean transformation using visual management

This time we follow a small team of engineers that is responsible for roof constructions. We witness the Lean Transformation, as part of the second effort to adopt Lean Methodology, after the first shipwrecked some years ago. Koen, who got the new role of Lean Coach, identified the roof construction team as a potential bottleneck. The management team, having all read “The Goal” by Goldratt, supports his choice.

Business case

The team consists of 5 designers, Gary acting as supervisor. The group is seen by project leaders as a difficult bunch, delaying projects in general. They always complain about workload, the work is always later than promised and also changes are sent one or two days after delivery of the package. To avoid the wrong materials being ordered, the project leaders delay a few days. Each project leader has his tricks to get the work done, the group is known to work best under pressure. Apart from being late, the roof construction team has been a source of many claims.

Current condition

Since the work is handed from the project leader directly to the individual designer, supervision and workflow management does not take place. Although end dates are expected, this is not visible in any way. Their perception of the group is chronic overload, so they feel not responsible for overdue work. An extra complication is the flow of small updates in drawings. During the day, updates are expected as immediate actions, thus interrupting the main workload.

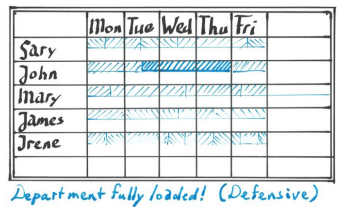

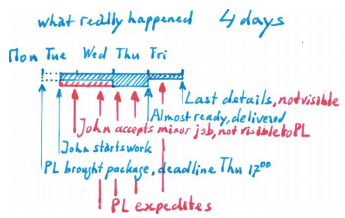

The team is cynical about this new initiative and resists the extra bureaucracy. When pushed, the first draft of the board illustrates the full workload. Koen keeps asking questions and, as an example, tries to get John’s story of the highlighted task. John remembers that he got the package on his desk Tuesday morning, and that the deadline was Thursday, end of day. Also, John told that he underestimated the task at first, and only on Thursday did he stop accepting other work. By working over lunchtime, the package is delivered just in time. Some last details he did on Friday, knowing that ordering materials would be later. On Friday evening he sent the package with updates. John is proud of his effective flexibility and Koen does not criticize. The team is encouraged by John’s story, and they confirm the planning mechanism. James admits even now deadlines are not met, even in a calm period. “When you do not know what comes next, it is tempting to take more time and deliver a perfect job”. Gary explains, how the system requires the supervisor “to fill the budget”, as the planning board shows.

Ideal condition

Koen tries to break the passive, reactive attitude of the group by provoking them. Imagine the team would work like a pit stop crew: having 50% free to play table tennis! But, as soon as a task comes, it will be handled by the whole team as a challenge. After some hesitating remarks, Gary explains this would be impossible. The team has to write hours, and his target is to have more than 90% of project hours. Irene adds to that: “We have been honest about extra capacity some years ago, as a result overwork was banned and a vacancy was cancelled”. Koen decides that management has to demonstrate commitment by talking to the team first.

Koen tries to break the passive, reactive attitude of the group by provoking them. Imagine the team would work like a pit stop crew: having 50% free to play table tennis! But, as soon as a task comes, it will be handled by the whole team as a challenge. After some hesitating remarks, Gary explains this would be impossible. The team has to write hours, and his target is to have more than 90% of project hours. Irene adds to that: “We have been honest about extra capacity some years ago, as a result overwork was banned and a vacancy was cancelled”. Koen decides that management has to demonstrate commitment by talking to the team first.

Design the target condition

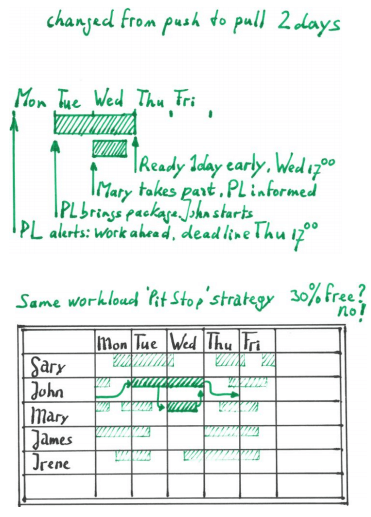

The manager joins the second session and assures the team that no one will be sacked. He even explains to Gary that all idle hours between an early finish and a next start can be booked on the first project! The team can hardly believe this, so the manager explains that some fair split of hours has to be made for projects. But he also explains that speed is critical; if the team can win a day on a project, the full company will benefit. And if the team slows down the work a little to balance workload, that may seem good for the team itself, but it is a waste for the company. Together with the manager, they analyze how the example of John could have been processed the new way.

The manager joins the second session and assures the team that no one will be sacked. He even explains to Gary that all idle hours between an early finish and a next start can be booked on the first project! The team can hardly believe this, so the manager explains that some fair split of hours has to be made for projects. But he also explains that speed is critical; if the team can win a day on a project, the full company will benefit. And if the team slows down the work a little to balance workload, that may seem good for the team itself, but it is a waste for the company. Together with the manager, they analyze how the example of John could have been processed the new way.

As a start, the project leader could look ahead on the work package. The manager takes action to inform project management about this new rule. With the look ahead, John could have made a direct start, and check if the amount of work would be as estimated. In this case, the unexpected extra work is signalled in time, and John can separate some tasks to Mary. Wednesday they could have worked parallel on the package. With hindsight, the package would have been finished Wednesday and fully completed at once. The manager explains that this would be fantastic, imagine each design time would behalf, and also the hassle of expediting would be history?

Implementation by kaizen event

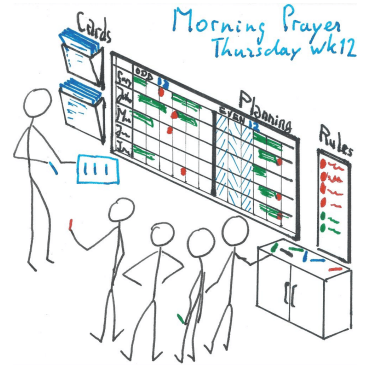

During a single day, the team develops and organizes the new work method. In a daily “morning prayer”, the team assembles at the new vision board. It has a two-week horizon, and uses odd and even weeks to avoid duplicating information. Workload and critical tasks are discussed; the first few days Gary takes many action items to explain the new method to project leaders. After some days, the team starts developing a list of rules, containing the standard actions.

Next to the morning prayer, the work method during the day is equally important. A project leader bringing work to one of the designers is kindly invited to the board where the details of the task are documented on an A5 card. The card is held by the designer working on it and acts as a task logbook. Key information is now recorded and some values are copied to the visual board. Deadlines become clear, and because the team does not exceed deadlines, the expediting habit ends within two weeks. The cards can be used for reference and analysis since the board is cleared after a week.

Closeout

Closeout

The manager visits the team several times and comes to the Morning Prayer twice. He compliments them on the achievement and tells other groups to go and see how the roof team organizes their work. This recognition is appreciated; the team grew from a defensive closed team into an example setting team that brings more improvement ideas.

Comments

No comments currently.