Lean project selection: How to avoid the top-down and bottom-up trap

Although powerful, when many projects are identified in this bottom-up way only, management may become nervous. The program will be perceived as an uncontrolled missile. This is not only caused by the management task to remain in control; alignment of the initiatives is necessary to avoid clashes of suboptimization. And any team member will appreciate learning how their project will contribute to the company’s performance. We will start from the extremes of top-down and bottom-up project selection, to propose a balanced approach. The frontline leader can play a pivot role, connecting top-and-down.

Top-down project selection, funnels and charters structure

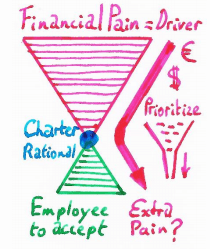

When a Lean program is guided by a consultancy firm, the contract may contain a result bonus (although in the Netherlands this is considered unethical). The Master Belts of the consultancy firm will identify areas for direct, bottom-line impact. Of course, their first interest is to satisfy the voice of the CEO. When interacting with the organization they will find volunteering teams to take on the challenge. The business cases (the “charters” in Lean Six Sigma language) will be agreed. And the work can start. A Lean Team is trained for eventual handover. And a long list of potential projects will be developed and dealt with in regular “funnel” meeting to set priorities.

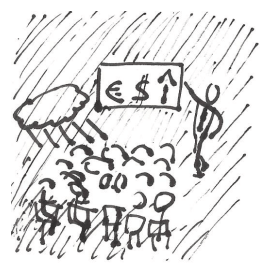

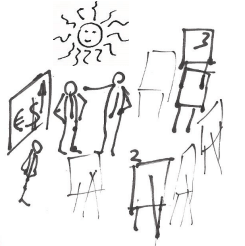

The process is a top-down translation of managerial goals into bitesize chunks of charters. Since the charters are prioritized for business impact, the employees may be eager to join … but also the projects may not reflect the daily pains of work. Possibly daily work will be more complicated when new rules and checks are developed? We illustrated this with a meeting structure in which the employees listen to a presentation by the consultants.

The process is a top-down translation of managerial goals into bitesize chunks of charters. Since the charters are prioritized for business impact, the employees may be eager to join … but also the projects may not reflect the daily pains of work. Possibly daily work will be more complicated when new rules and checks are developed? We illustrated this with a meeting structure in which the employees listen to a presentation by the consultants.

It will certainly work, although we might ask ourselves if this system is sustainable. Would the employees after the first enthusiasm feel empowered? Or could they feel exploited? Do they volunteer because of their career perspective and the clear support of the Management team? If the projects introduce new and higher work demands, without taking away barriers in daily work, the program may fade away after the initial euphoria, like most other programs? Or it will require continuous daily push by the Lean Team. Both are indications that we failed to engage the workforce, even if all team members express their support. The consultancy firm will leave after having collected the maximum bonus. They will repeat the process at their next client, motivated by good results, and refer on their website. Sustaining is the responsibility of the abandoned Management Team, isn’t it? And the Lean Team just received a handover they could not refuse? If this is the outcome, the company will have developed a clear allergy for future initiatives. A missed opportunity with lasting impact.

It will certainly work, although we might ask ourselves if this system is sustainable. Would the employees after the first enthusiasm feel empowered? Or could they feel exploited? Do they volunteer because of their career perspective and the clear support of the Management team? If the projects introduce new and higher work demands, without taking away barriers in daily work, the program may fade away after the initial euphoria, like most other programs? Or it will require continuous daily push by the Lean Team. Both are indications that we failed to engage the workforce, even if all team members express their support. The consultancy firm will leave after having collected the maximum bonus. They will repeat the process at their next client, motivated by good results, and refer on their website. Sustaining is the responsibility of the abandoned Management Team, isn’t it? And the Lean Team just received a handover they could not refuse? If this is the outcome, the company will have developed a clear allergy for future initiatives. A missed opportunity with lasting impact.

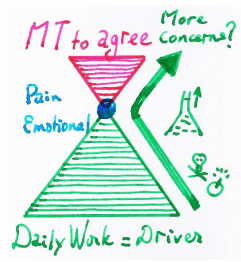

Bottom-up project selection, the avalanche of mixed topics

The extreme different approach, several times advocated by myself, may appeal to different management teams. Connecting to existing initiatives, this approach is more natural in the start. It will miss the shock effect of external consultants being visible in all areas. Since the internal Lean Team must accommodate the work, typically the start will be relatively slow. Topics are chosen from daily work issues, and maybe do not appeal at the Management levels? The process is a bottom-up translation of pains that are felt in the primary process of the projects. Although the business impact is recognized, the teams need encouragement to express the impact. (Fearing for budget cuts or even job reductions.) This time the typical happening is a quarterly poster presentation in which management does act positive, but with an underlying feeling that this is not solving major issues yet. This approach will also work but at the same time raise some concerns about sustainability. Starting this way will empower the employees for the first few waves. But sooner or later the disconnection with business goals will turn the program into another initiative that fades away … until the next effort? Which will be top-down of course.

The extreme different approach, several times advocated by myself, may appeal to different management teams. Connecting to existing initiatives, this approach is more natural in the start. It will miss the shock effect of external consultants being visible in all areas. Since the internal Lean Team must accommodate the work, typically the start will be relatively slow. Topics are chosen from daily work issues, and maybe do not appeal at the Management levels? The process is a bottom-up translation of pains that are felt in the primary process of the projects. Although the business impact is recognized, the teams need encouragement to express the impact. (Fearing for budget cuts or even job reductions.) This time the typical happening is a quarterly poster presentation in which management does act positive, but with an underlying feeling that this is not solving major issues yet. This approach will also work but at the same time raise some concerns about sustainability. Starting this way will empower the employees for the first few waves. But sooner or later the disconnection with business goals will turn the program into another initiative that fades away … until the next effort? Which will be top-down of course.

Balanced approach, a viable improvement process?

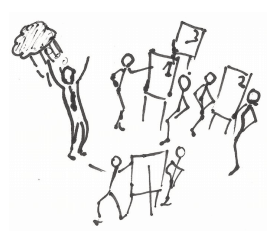

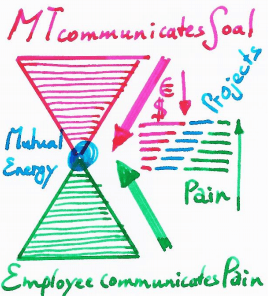

Both extremes are eventually unsuccessful. The challenge will be to translate any startup situation into a sustainable and viable improvement process. When irritations and disappointments can be openly expressed, it will be possible to develop into an effective program which is an integral part of the business. For the top-down approach, the initial high-level visibility program must be reconnected to the daily work problems. Maybe reducing the ambition to realistic levels. The bottom-up approach needs to increase ambition and strive towards higher visibility and business impact. The intervention for both situations is the same: project selection must become a two-way process. A market place where business impact and daily work pains are connected.

First, we recapitulate the previous extremes:

- Top-down approach: huge forums in which projects are presented to the MT, focusing on impact. The meeting is communicated with a PR message. Probably a prize is awarded to the highest impact team?

- Bottom-up approach: huge markets in which poster presentations are given to the community. Management Team is invited as guests, probably also for opening and closing the session. It is hard to identify the impact because teams are intrinsically motivated in the detail, and hesitant to claim results. A balanced approach would be more complex at first sight, because it requires a synchronized preparation, both top-down as bottom-up. The above two sessions are only reporting the results, and we need to align projects at the start. But is not the closure of a wave of projects at the same time the start of a new wave?

- Balanced approach: an interactive market in which both improvement teams and Management Team reflect on the previous wave. In the second part of the meeting, new projects can be co-developed. This second part will act as a pivot between two worlds, it will give a boost to the teams while at the same time allowing management to translate their issues into improvement charters.

This time, the MT brings the business drivers, and the teams bring their pains in daily work. Based on win-win, the outcome is energizing for all participants. The teams will feel supported, and the MT will be less uncomfortable. Maybe some business problems are not yet addressed and will need a different approach? Maybe some inevitable pains can be explained? The balanced approach will always be a tradeoff between the two extremes. Each organization will bring its specific challenges. But the Lean Team can continuously aim to develop the project selection process in a pivoting way between top-down and bottom-up, balancing business goals and pain of daily work.

The balanced approach will always be a tradeoff between the two extremes. Each organization will bring its specific challenges. But the Lean Team can continuously aim to develop the project selection process in a pivoting way between top-down and bottom-up, balancing business goals and pain of daily work.

You might think I advise the third, balanced approach? No, not; it is indeed too complex for a start. My advice is, to start any approach but change timely. The continuous change is good anyway. A static model will start boring both the employees and the management; after a few waves, the burning platform will be lost.

Maybe the difficulty is not the approach, but the lack of perspective. Some situations require a path starting at the bottom, like climbing a mountain. But the most successful teams will consider the entire terrain, from different vantage points. Some obstacles are more visible from the top, but they are real whether they are visible from the bottom, or not. The people with vision, maybe they have previously seen things from the top. We call them guides. Or they have so much experience they can envision hidden obstacles, even on paths they never climbed before. We call them experts. People who can get us to see that which was hidden from us, we call them coaches.

Thanks for the comment, sorry I did not notice earlier,

Fully agree with your comments, having the view upwards to strategy and downwards to shop floor is indeed where the coach is vital, and maybe that is what team-leaders should be capable of? (but often they are not and need help?

Kind regards Leo Monhemius

Either approach sounds like a management team not fully understanding what Lean really is and wanting a quick fix before the next shareholder meeting. At the risk of banging on and on and on, LEAN IS NOT AN IMPROVEMENT METHODOLOGY! It is, arguably, the most significant advance in our understanding of how a good leader/manager/supervisor should think, believe, act and behave.

If the leadership has not changed its thinking from the more common Command & Control to Lean, then they should stick to Six Sigma. If the Ed&Training department has been outsourced because learning by all is not regarded as vital in this fast-changing world, then the organisation will slowly die. is not If they do not practice Genchi Genbutsu they should leave it to their priesthood of Six Sigma belts. If they do not have a robust strategy development and deployment process (Hoshin Kanri), then you will get either Top-Down or Bottom-Up approaches which, as you say, are likely to fail.

Excellent posting, Lee. Too often, organizations choose only Top Down or Bottom Up methodologies for choosing which improvements to implement, but I feel a hybrid mix of the two tends to yield more positive results for ALL parties involved and doesn’t alienate the production associates by failing to address their concerns, which in turn can accelerate the whole culture change and make it much less threatening. Small victories for the shop floor associates can and will energize them them to help with larger issues that translate a larger impact to the bottom line, but I think these activities need to happen first—while the larger “fish to fry” projects are being identified and quantified. Great post!