Balance between control and improvement

Balance between control and improvement: why front line leaders should be given pivot roles

Lean basic process control symptoms:

- Front line leaders give up and spend time in meetings instead of shop floor

- Near misses in primary work. Informal procedures are followed;

- Pride of workmanship not recognized at higher organization levels

- Cost driven Lean Six Sigma program

I had several situations in which the momentum of the program brings criticism to silence and at the same time becomes a threat for continuity in the basic process. For process industries and healthcare, this can cause major risks.

Imagine resistance is justified. Pushing harder does not work: “grass does not grow faster when you pull”. Pushing for results without listening to the reasons behind will frustrate the first-line supervision. We do not respect anymore their primary responsibility to balance process control and process improvement.

One of the core values of Lean is listening to those who do the work. Employees will never encourage changes that undermine their self-control of basic tasks. Pressure of shareholders will make it tempting for management to stimulate those employees that propose daring improvements, even if other employees do not support.

At first sight, a Lean Six Sigma program may seem successful. But, if the basis of Lean is not recognized, the program will certainly fail. A first signal will be a dramatic increase in small incidents, but will these be reported by the supervisors?

At first sight, a Lean Six Sigma program may seem successful. But, if the basis of Lean is not recognized, the program will certainly fail. A first signal will be a dramatic increase in small incidents, but will these be reported by the supervisors?

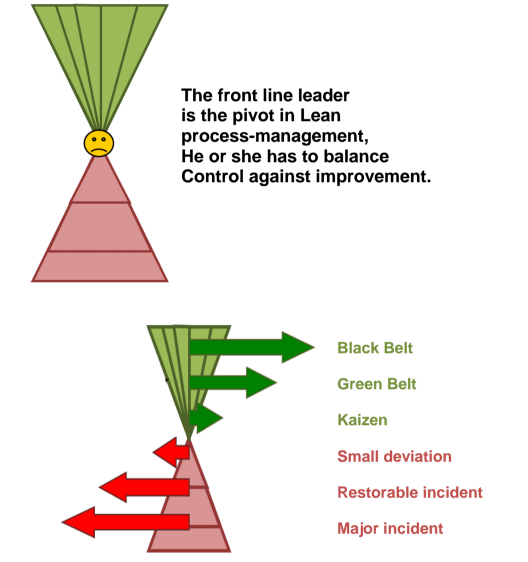

In the pictures, the role of the first-line supervisor is illustrated. The foreman looks upward in the organization to many parallel staff areas that impose processes upon him or her. HR reviews, financial data, IT, Logistics, etc.

Often we do not respect how many avoidable costs (red arrows) are prevented by supervision – it is taken for granted. Let us give supervisors the authority to accept improvements (green arrows) to the level that the risks remain under control.

I’m a little baffled by the graphic. Line leaders and workers should be a part of solutions and risk management. The graphic looks like you imply black belts generate big negative consequences.

Thanks for your comment.

I fully agree that Line leaders should be part of solutions and risk.

Maybe I have written too much confrontation style, but I have seen many situations in which the frontline leader controls the basic process in an informal way.

If these efforts are taken for granted by higher management, and if a black belt is judged upon bottom line results, the secondary metric can easily be forgotten.

I know several examples in which the cost of non-quality for a single project / process exceeds by far the benefits of a team of blackbelts for a year.

kind regards Leo Monhemius